The Keypad

The idea of having a keypad had been part of the project from its conception. The keypad in WMD operates: power on/off, reset, start/stop timer, reset timer, eject DVD, and sets hours/minutes/seconds on the timer. I also added a keylock, which can disable or enable the keys.

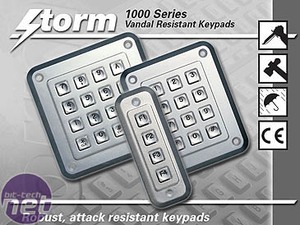

The keypad used is a Storm 1000 Series vandal resistant keypad. As the factory for these was in the UK, the bit-tech staff did some digging for me and managed to lay hands on a version which features red-illuminated key symbols (thanks guys). I played around with it on arrival...now where should I put that keylock? You can see from the image that the bezel is a powder-coated silver-grey colour, the keys are silver and the box behind is extruded aluminium, which had been powder-coated black.

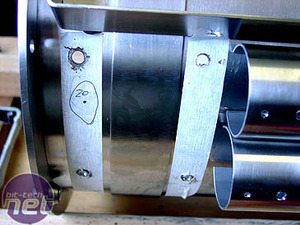

I used a level, placed on a steel ruler and laid across two of the bolts in the flange of the main cylinder, to give me an idea of the exact front of the case (shown facing directly upwards in the picture). I wanted the flat face of the keypad to face forwards. It meant I would have to cut a curve in the back of the keypad box, with the top having more taken off than the bottom: as the keypad would end up sitting slightly below the centre-axis of the case. To assist in marking the box, I printed out a circle the exact outside diameter of the cylinder.

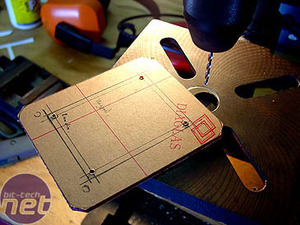

Laying the keypad box on this circle allowed me to draw an accurate curve to match the curve of the case. I then clamped the box and began cutting with the Dremel. As it was aluminium, I could cut slightly outside the line, knowing I could file it accurately later. Cutting on a curve was harder than a straight line and this gave me room for error.

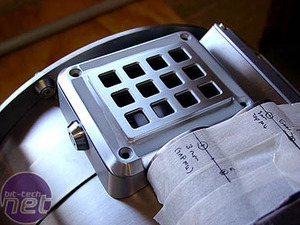

With the back cut out, you can see how the bottom end of the box is thicker - this allows the box to sit slightly lower than the centre of the case cylinder, but still have the flat surface of the keypad facing mostly forwards, not angled too far down. I even marked the centre axis of the case on the side of the box as a guide. A lot of filing and wet-sanding later, the keypad bezel and box are nice and shiny.

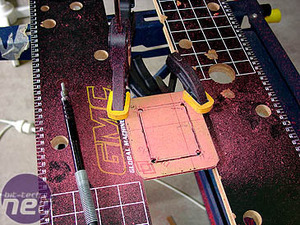

I drilled a hole in the bottom of the box for the keylock. As the keypad sits astride one of the 40mm steel bands that 'encircle' the case, I needed to cut notches, top and bottom, to allow the box to sit flush to the cylinder.

I left some of the paint still on the bezel, as that part will be covered later by stainless steel. With the keypad in place, its position on the steel band is obvious. It sits tightly against the ends of the front cylinders and butts up against the bottom of the timer box.

The keylock can be seen here, also the notches that enable the box to sit flush to the case. To mount the keypad, holes were drilled in the case....

...and the inside of the original mounting holes tapped to M5. I marked and drilled a 20mm hole for a cable gland (to carry the keypad wires into the main case).

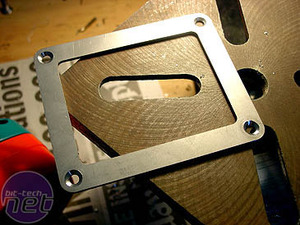

The penultimate finishing touch is a laser-cut stainless steel surround for the keypad. This was drilled and countersunk, being fixed with M5 counter-sunk socket screws, which also serve to hold the keypad bezel to the box behind it. The steel surround was polished later.

The final touch was to make a red plexi insert, to sit between the keypad face and box, allowing me the option of lighting it to create a glowing red line around the keypad. This was marked, using the keypad as a template, drilled and cut out of 3mm red plexi.

After drilling out the bezel holes a fraction, the whole lot was assembled. It ended up looking pretty reasonable....

...and fitted well. The box is held on with M5 screws and washers which screw into the threaded holes in the keypad box, from inside the case. Now, a special keypad needs a special key. We've all seen the movies, where the missile silo guys have the fancy keys to launch Armageddon. I needed to make myself one of those! The key that came with the keylock was a boring yellow plastic number. I had a spare, stainless steel USB socket cover, and decided to use this to cover my key.

I first cut the USB cover in half, bolted it together, and marked and filed the corners. I still wasn't satisfied, so I cut some more off, leaving an opening in one end of each piece, then filed the corners again. I cut a section of the plastic part of the key, filed and vinyl-dyed it black. Some more drilling and polishing, and a few M3 screws cut to size, plus the addition of the chain from my army dog-tags and voila! Insta-cool-key!

Nyloc nuts hold the sides on, with the chain passing around the screw in the end (a stack of small washers surround this screw, separating the ends of the key covers).

TO BE CONTINUED....

...shortly in WMD Part III, where I'll cover the frames that support the case and the sliding motherboard tray, discuss the project concept vs. the reality (and other Zen stuff), polish lots of things, show some more pictures of the finished mod, and more!

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.